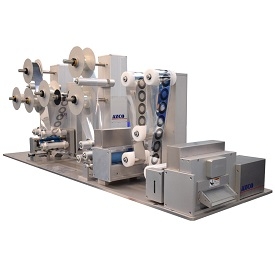

Fairfield, NJ – May 15, 2020 – AZCO Corp. has designed and manufactured a complete system to unwind four different materials from rolls, laminate them together, and then cut the finished product to a specified length.

The rolls of material which include PET film, aluminum coated PET with adhesive, and release liners, are loaded onto four separate cantilever design brake unwinds. A roll feeder pulls the materials off the unwinds and laminates them together. The product travels through a dancer accumulator and is advanced by precision ground urethan drive rollers. An internal guide directs it from the drive rollers into the knife assembly. A registration eye sees a mark which signals where to cut the product. The modular designed knife assembly is pneumatically operated, requiring 2.75 – 3 Bar [40 to 60psi] of regulated air pressure. An operator control panel is provided which includes an HMI color touch screen for easy setup and operation of the unit. All units are attached to an aluminum equipment table.

AZCO Corp. designs and manufactures modules and units used to feed, cut and place products. Their concept is based on a building block model. Standard modules and units can be purchased alone or in combination to build a solution that meets your unique needs. Standard units are in stock and can be customized to fit specific requirements.

AZCO Corp. is an ISO 9001:2015 certified company with over 35 years of experience developing solutions for a wide range of feeding and cutting applications. Made in USA.

For more information, contact:

Andrew Zucaro, President