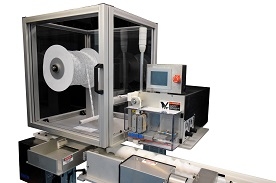

Fairfield, NJ – February 19, 2020 – AZCO Corp. has designed and manufactured a pouch dispenser for an application that required dispensing desiccant into bottles at a line speed of 80-90 bottles per minutes. The unit was special designed for controlled environments.

A roll of the desiccant material is placed on a motorized unwind which controls tension on the web and helps to ensure high accuracy and consistency. From the unwind the material is guided into the cantilever dual servo drive belts and self-feeds to the proper starting position. The optic system which is built into the knife cartridge tracks a position on the material. Once the material is indexed to the proper location, the knife assembly is triggered, making a cut. The desiccant pouch is dispensed into bottles below which are guided by a timing screw on an adjustable speed conveyor. An adjustable motorized equipment stand is included for easy mobility of the unit. A full Lexan enclosure separates the pouch from the outside environment. The unit is PLC controlled. An operator touch panel is provided which includes a touch screen for easy setup and operation. The unit requires 110VAC power and compressed air.

AZCO Corp. designs and manufactures modules and units used to feed, cut and place products. Their concept is based on a building block model. Standard modules and units can be purchased alone or in combination to build a solution that meets your unique needs. Standard units are in stock and can be customized to fit specific requirements.

AZCO Corp. is an ISO 9001:2015 certified company with over 35 years of experience developing solutions for a wide range of feeding and cutting applications. Made in USA.

For more information, contact:

Andrew Zucaro, President