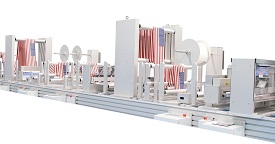

Fairfield, NJ – February 10, 2021 – Flexibility is an important key to success. AZCO Corp.’s building blocks of automation system offers you flexibility and options to design a machine configured to meet your needs. Modules can be quickly and easily installed or removed, based on your requirements. You can seamlessly integrate unwinds, cut to length, slitters & traveling knife assemblies, accumulators, laminating and perforating stations, and rewinds to handle all types of films, nonwovens, paper products, absorbent materials, foils, laminated materials, or high-performance materials. You can make changes to your machine and start making product in minutes.

At the foundation of this system is a SMARTFRAME which is designed for ease and convenience, and which has the capability to handle many different modular units. Modules are easily slid into place and mounted onto the frame. The frame is pre-wired and includes quick-connect connectors for power and air so you can just plug in and begin using. A master control panel monitors the entire process and gives you control over the system, including the ability to add and subtract modules as needed.

With the building blocks of automation, you get a machine configured to meet your requirements, for both current and future applications. As your business changes and evolves, the building blocks of automation gives you the flexibility and options to grow and expand. It enables you to be proactive and ensures that your success is firmly in your own hands.

AZCO Corp. is an ISO 9001:2015 certified company with over 35 years of experience developing solutions for a wide range of feeding and cutting applications. Made in USA.

For more information, contact:

Andrew Zucaro, President